QAQC Assistant Manager,Mie-ken, PM

【Confidential】QAQC Assistant Manager,Mie-ken, PM

Work Place:Kasumi- Plant (Mie-ken)霞工場 三重県四日市市霞1ー23ー2

Objectives of the Position

|

Main Tasks

|

A.1 Site Non-Conformance Management

A.2 Support Site Quality Management

A.3 Support Site Quality Control

A.4 Toller Quality Management

A.5 Support Management of Raw material & Product Specification / Assurance Agreements

A.6 Support Quality Communication, Reports and Training

Key shared accountabilities

|

Job Requirements (Minimum requirement to carry out the work)

品質管理/アシスタントマネージャー(管理職ではない一般職)

勤務地:霞工場 三重県四日市市霞1ー23ー2

■主なミッション

- 品質マネージャーを補佐し、ISO関連システムに基づいた品質システムの計画・活動・目標の実施を支援する。

- 原材料、中間製品、完成品の検査に関する品質管理手順、方針、基準に従って行動し、製品が品質基準を満たすことを保証する。

具体的には以下

A.1 不適合管理(NCM)の推進

- 不適合管理(製品やプロセスが定められた品質基準や仕様に適合していない場合に、それを特定・記録・分析し、是正・予防措置を講じる一連の管理活動) を主導する

- 生産部門および関連部署と連携し、品質不良の原因を調査し、製品の格下げや特別出荷を管理。

- 重大な問題の調査を主導し、地域品質プロジェクトに参加。再発防止のための是正・予防措置の効果的な実施を確保。

- 顧客向けNCM報告書の作成・確認を行い、正確かつ専門的な形で提出。合意された対応・期限をフォローアップ。

- 顧客苦情対応(補償含む)を推進し、ビジネスリスクを最小限に。苦情データを分析し、傾向を把握して改善プロジェクトを主導。

A.2 サイト品質管理の支援

- ISOシステムの構築・維持・監視・更新を関連部署と連携して実施し、認証取得を確保。

- ISO 9001の内部・外部監査および有効性確認を支援。

- 顧客およびサプライヤー監査に関する文書作成および品質マネージャーの支援。

- マネジメントレビューの準備・運営を支援。

- 品質改善プロジェクト・タスクの実施支援。

A.3 品質管理(QC)の支援

- 品質管理手順の確立を支援し、試験の標準化活動を担当。

- QA/QCラボの機器をマニュアルやサプライヤーの指示に従って修理・調整し、実験の正確な実施を保証。

- ラボ機器の設置・使用・保守を適切に行い、品質を確保。

- 検査機器の保守を通じて品質基準を維持し、手順・基準・機器に関する改善提案を実施。

A.4 外部委託先の品質管理

- 委託先と協力し、完成品の試験が既定のシステムに従って行われていることを確認。

- 委託先の不適合対応を調整し、リスク最小化のための最適な解決策を協議。原因特定と是正・予防措置の実施を確保。

- 委託先との定期会議を開催し、継続的改善を推進。必要に応じて改善プロジェクトを開始。

A.5 原材料・製品仕様/保証契約の管理支援

- 品質マネージャーのもと、原材料・製品仕様および契約の管理を支援。

- 定期検査データの分析を通じて傾向や逸脱を特定。

A.6 品質コミュニケーション・報告・教育の支援

- 品質マネージャーのもと、報告書を作成し、地域品質管理チームと共有。

- 関連する品質データ・分析・報告書を作成・管理し、必要に応じて関係者へ提供。

- 生産担当者に対し、品質試験、機器の衛生管理、整理整頓の推奨方法を教育・指導し、必要に応じて是正措置を実施。

- 品質文化の促進(例:World Quality Week、月例TPU(製品名)会議、月例会議など)を通じて、従業員の品質意識とスキル向上を図る。

求められる条件

学歴

- 化学分野の学士号以上

職務経験

- 製造や研究開発、品質保証分野での5年以上の経験

技術・専門知識

- 化学製品の生産および品質保証に関する優れた知識

- ISO 9001、IATF 16949、ISO 17025、ISO 18001、ISO 14001などの品質・環境・安全基準に関する理解

- 不適合管理(顧客苦情対応)に関する要件の理解

- 英語での読み書き・会話能力(活動内容の報告書作成・チャットやメールへの対応など、アシスタントマネージャーに求められる英語力は主に書く・読むの英語力で、会話やディスカッションには自信のない方でもご入社後、英語で業務をすることに抵抗がなければぜひご応募下さい)

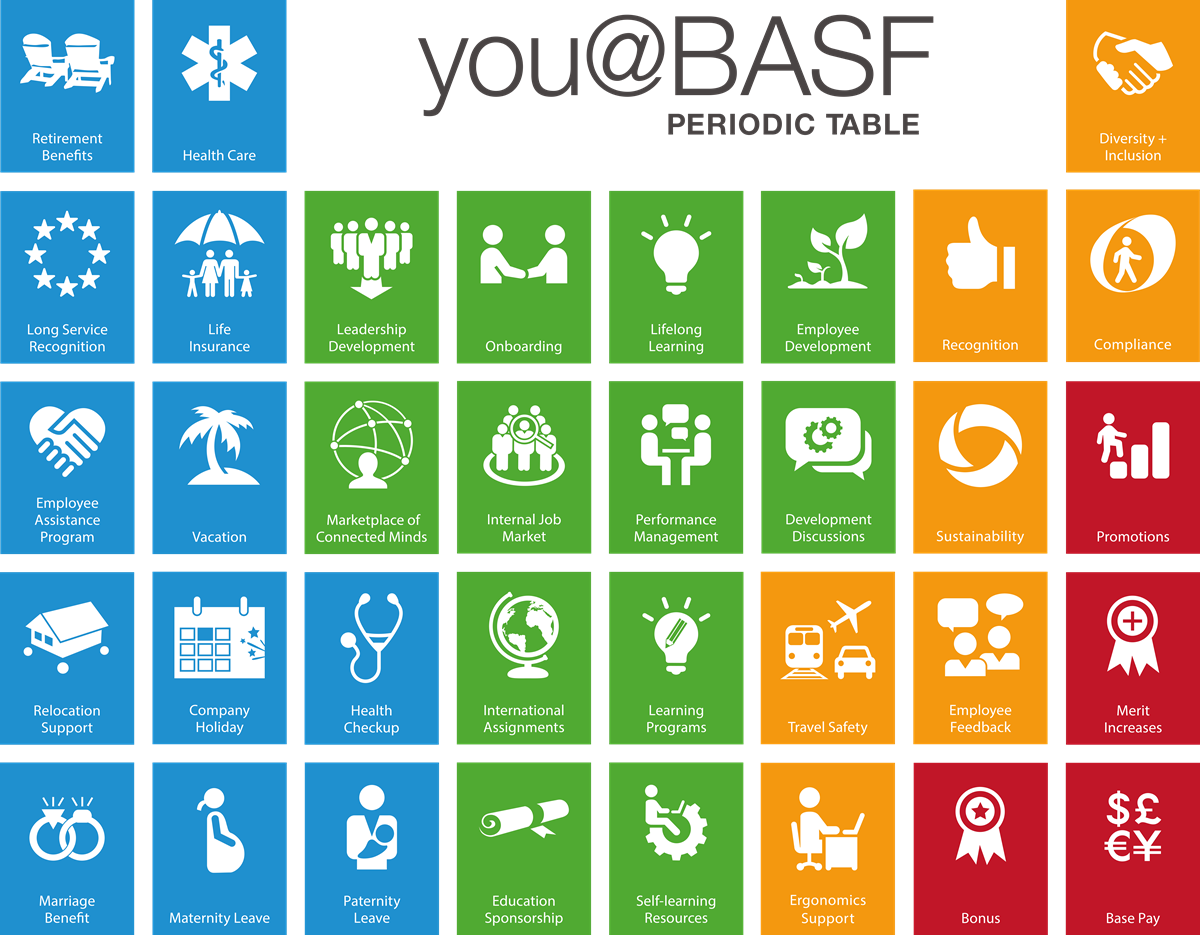

A unique total offer: you@BASF

At BASF you get more than just compensation. Our total offer includes a wide range of elements you need to be your best in every stage of your life. That’s what we call you@BASF. Click here to learn more.

A unique total offer: you@BASF

At BASF you get more than just compensation. Our total offer includes a wide range of elements you need to be your best in every stage of your life. That’s what we call you@BASF. Click here to learn more.

Working at BASF: We connect to create chemistry

We are proud of strong history of innovation, which has helped make us who we are today – the world's leading chemical company. Every day, our global team of over 120,000 individuals work together to turn visions for sustainable solutions into reality by connecting with one another and sharing our knowledge.

The right people are crucial for our sustainable success. We aim to form the best team by bringing together people with unique backgrounds, experiences and points of view. Our differences make us stronger and more vibrant. And an open, creative and supportive work environment inspires us to achieve exceptional results.

Your application

Here you find anything you need to know about your application and the application process.

Contact us

You have questions about your application or on how to apply in Europe? The BASF Talent Acquisition Europe team is glad to assist you.

Please note that we do not return paper applications including folders. Please submit copies only and no original documents.

Yokkaichi-shi, JP