Production Officer

Objectives of the Position

- To operate process plants for manufacturing of finish product by monitoring and control of process parameter

- Operates, regulates, and monitors batch productions to produce Engineering Plastics products during shift. Works in field under supervision of the shift leader

Main Areas of Responsibilities and Key Activities

- Performs routine tasks and assignments through practical application of industry standards involving production operations, Mixing & feeding of RM & packing of FG.

- Applies considerable knowledge in the operation, maintenance, methods, procedures and techniques of applicable plant equipment and safety requirements specific to the area of assignment.

- Basic House Keeping of machine and workplace

- Performs routine troubleshooting.

- As per site layout responsible for Production area.

RCMS Responsibilities:

- Familiarize themselves with MSDS of hazardous substances within workplace.

- Perform the role as defined in On-site Emergency Plan to mitigate the emergencies.

- Follows requirement / procedure related to EMS/ RCMS.

- To take EHS requirements into consideration prior to any activity or work to make sure that the launching work is safe to prevent/minimize the safety risk, environment pollution and other potential hazards.

- Attend all EHS training as required.

- Have the responsibility for promptly reporting to direct supervisor in case of any incidents and near miss or exposure to hazardous substances.

- Always practice good housekeeping and keep workplace clean.

- Risk analysis.

- Develop safe working skills and habits.

- Familiarize themselves with MSDS of hazardous substances within workplace.

Key Activities:

- Maintain the Production, Quality & Safety

- Smooth Plant operation

- House Keeping

Job Skills

- Equipment Knowledge of production / packaging equipment, and knowledge of instrumentation / control system, and automation, including technical standards

- Process Unit Operations

- Safety

- Communication

Job Requirements

- Diploma in plastic processing / ITI with 3year experience in polymer plant

- 3 -15 Years Working Experience

- Technical & Professional Knowledge in Extrusion equipment & compounding process

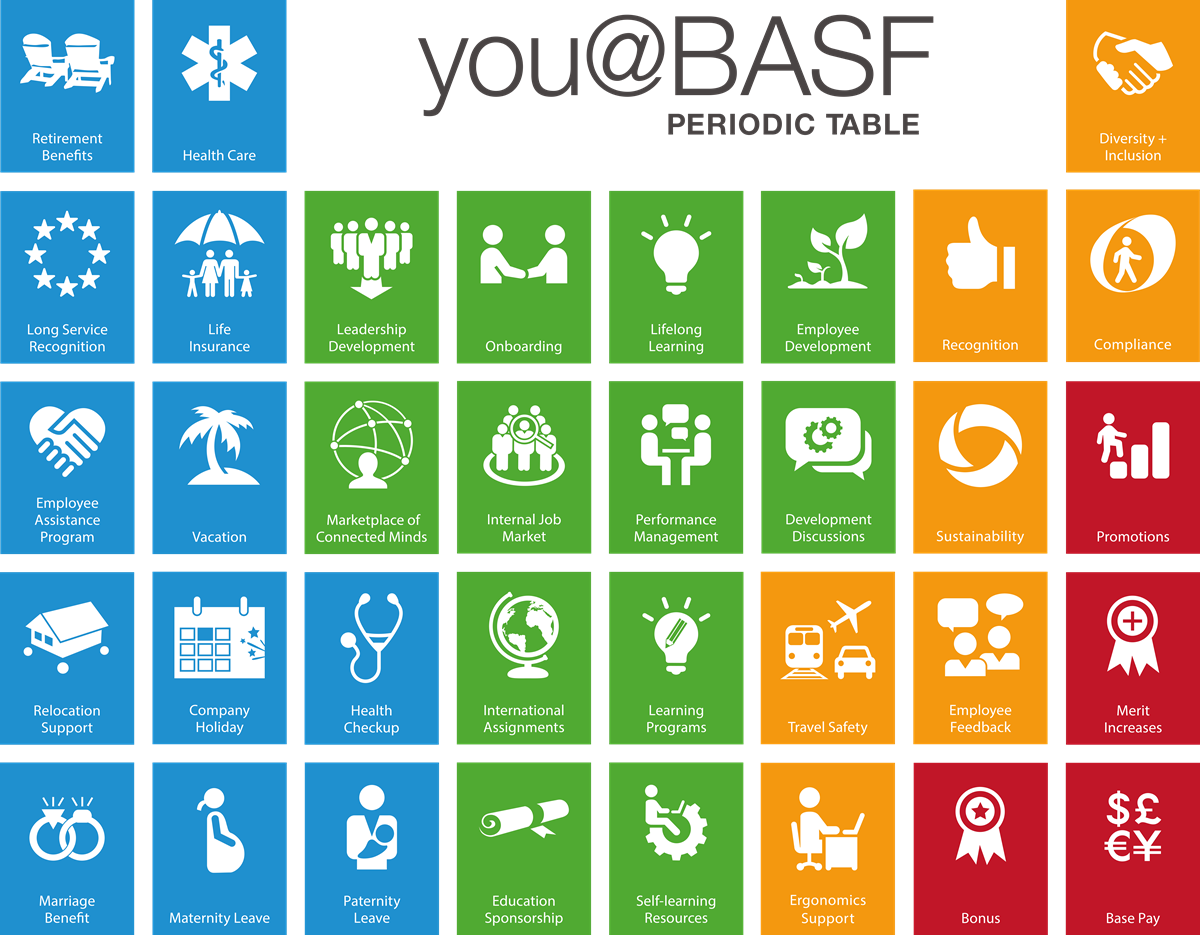

A unique total offer: you@BASF

At BASF you get more than just compensation. Our total offer includes a wide range of elements you need to be your best in every stage of your life. That’s what we call you@BASF. Click here to learn more.

A unique total offer: you@BASF

At BASF you get more than just compensation. Our total offer includes a wide range of elements you need to be your best in every stage of your life. That’s what we call you@BASF. Click here to learn more.

Working at BASF: We connect to create chemistry

We are proud of strong history of innovation, which has helped make us who we are today – the world's leading chemical company. Every day, our global team of over 120,000 individuals work together to turn visions for sustainable solutions into reality by connecting with one another and sharing our knowledge.

The right people are crucial for our sustainable success. We aim to form the best team by bringing together people with unique backgrounds, experiences and points of view. Our differences make us stronger and more vibrant. And an open, creative and supportive work environment inspires us to achieve exceptional results.

Your application

Here you find anything you need to know about your application and the application process.

Contact us

You have questions about your application or on how to apply in Europe? The BASF Talent Acquisition Europe team is glad to assist you.

Please note that we do not return paper applications including folders. Please submit copies only and no original documents.

Panoli, IN